Material Growth

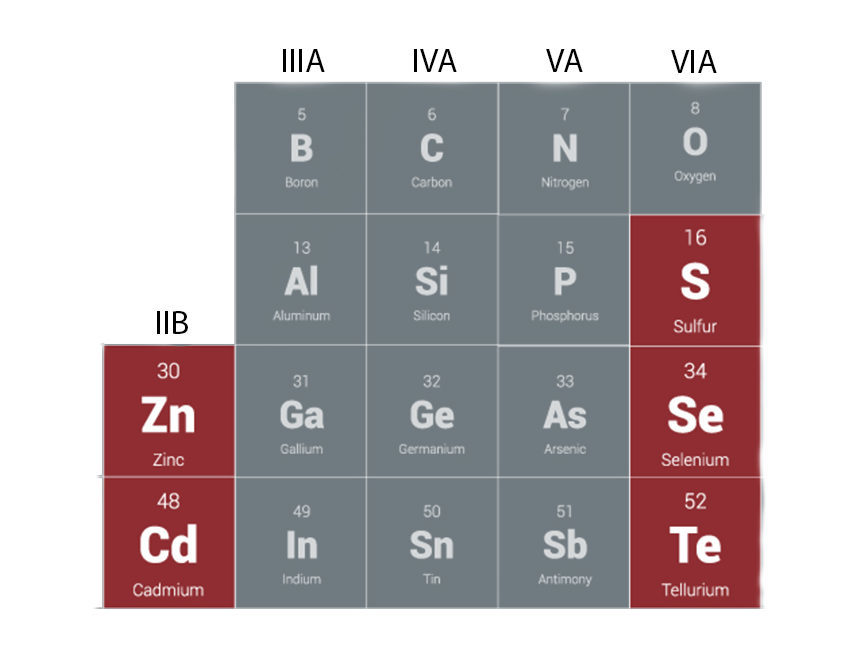

IIVI Aerospace & Defense is the industry leader in production of infrared optical crystals and other specialty materials. II-VI Aerospace & Defense is one of the foremost manufacturers of germanium products for military infrared applications.

Materials are the Core Building Blocks of our Corporation:

- Ceramic Yag; Ceramics Center of Excellence

- YAG; YLF

- KNbO3:Fe

- SiC and AlSiC Casting Facility

- Single Crystal SiC

- Diamond Growth Facility

- Thermo Electrics

- MS ZnS, ZnS and ZnSe Growth Facilities

- Sapphire Growth Facility

- Germanium Growth

- UV and Chalcogenide Glass

- Ceramic Radomes

- LO Films

Strategic Materials Foundry

The II-VI Aerospace & Defense Strategic Materials Foundry produces a wide variety of materials with unparalleled quality that are utilized in a broad range of applications. With an experienced staff of material, scientists, physicists, process engineers and operations personnel, the Foundry is able to deliver dependable products in volume as well as develop new materials to support emerging applications. II-VI Aerospace & Defense assures that each crystal will perform to customer specifications and maintains traceability on all materials produces from the raw powders to the finished laser components.

Growth Capabilities

Various growth techniques such as Czochralski (CZ), Bridgeman, Solution and Top Seeded are utilized to grow a wide array of materials. II-VI Aerospace & Defense has over 70 growth stations and a focused Foundry team that enable II-VI Aerospace & Defense to grow the finest crystals in the world.

Materials Produced by II-VI Aerospace & Defense:

II-VI A&D produces polycrystalline germanium optical blanks up to 18 inches in diameter.

Germanium material grown by II-VI A&D features:

- Tightly controlled resistivity with overall values ranging from 3-40 ohms-cm.

- Custom grown and near-net shapes for domes and irregular windows to minimize material fabrication costs.

II-VI A&D's engineers are experienced with a wide range of optical materials for infrared and visible applications. We can provide assistance in the selection of the material best suited to meet your requirements. Contact us to support your product needs.

II-VI A&D has an internal process for recycling germanium scrap. Ge Recycling II-VI A&D grows germanium crystals to support the IR products we produce. We have the radioactive certifications to handle thoriated coatings at our site. II-VI A&D is experienced in this area as we deposit thoriated and non-thoriated coatings into IR windows. We are compliant with the proper disposal methods to maintain our certificates and are experienced in our recycling process. We maintain our ISO 9001-2000 + AS9100B certifications which are necessary for consistent and repeatable procedures

II-VI A&D provides advanced ceramics solutions for military programs, automotive applications, and space-based systems.

High Temperature Ceramic Patterns for Radomes & Antennas

II-VI A&D has developed proprietary techniques to coat and pattern high temperature materials for high-speed radome applications. Our proprietary disruptive patterning technology is the result of continuous collaborative development efforts with DoD agencies.

-

Ultra-Precision Conformal 3D Patterning

-

High Temperature Solutions > 1000˚C

-

Radomes with Frequency Selective Surface Patterning

-

Large Format EMI Shielded Antennas

-

Custom RF & Pattern Layout Design Optimization

-

Conductive Patterns and Conformal coatings on Internal & External surfaces

-

Diverse Material Systems including CMCs

-

Leading Technology, High Resolution, Seamless, Scalable, Proven

Click here for more information on patterned ceramics on our Max Levy website.

Max Levy Autograph has been part of II-VI Aerospace & Defense since 2014.

For Military program opportunities, please contact us at Tel: (215) 842-3675 or Email: Jennifer.Lehman@iiviad.com

Additional patterning capabilities include:

-

EMI/RF shielding for High Transmission Optical Windows & Domes

-

Boresight/Riflescope Reticles for EO/IR applications using edge-illumination

-

Solutions using large format Flexible Films for airborne platforms

Polished Ceramic YAG

Ceramic YAG has many advantages over single crystal YAG for various high power applications. II-VI A&D has internal capability to manufacture, fabricate and coat ceramic YAG. Applications include LIDAR and High Energy Lasers (HEL).

-

LIDAR Integration

-

Edge & Long-Face Bonding Capability

-

High Uniformity Doping Options

-

Custom Coatings

-

High Purity Powder-Based Slab Production

For program opportunities, please contact us at Tel: (951) 926-2994 or Email: Kevin.Kelly@iiviad.com

Reaction Bonded SiC & MMCs

SiC Optics

Silicon Carbide Mirrors

-

Directly Polished RB SiC for Lightweight Applications

-

Reaction Bonded SiC Mirror Substrates for HELs

-

Al/SiC MMC Mirrors for low CTE matching

Mirror Substrates and Optic Housings can both be fabricated in complex shapes and in Al/SiC MMCs.

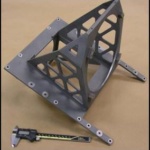

Cast Al/SiC Optic Housing

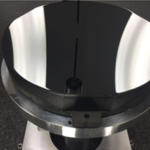

Directly Polished SiC Mirror

Reaction Bonded (RB) Silicon Carbide

-

Lightweight Directly Polished Mirrors for Space-Based Telescopes

-

Aspheric & Spherical Mirror Substrates

-

Low Mass Laser Scanning Mirrors

-

Ribbed-Back SiC Mirror Substrates

Al/SiC Metal Matrix Composites (MMCs)

-

Large 2m Square Stage Structures

Advanced Structural & Technical Ceramics

-

Laser Ceramics

-

Optical Ceramics

-

Silicon Carbide products

-

Transparent ceramics

Glass Products

-

Fused Silica glass

-

Glass-ceramics

-

Mirrors

-

Optical substrates

II-VI A&D is a member of both USACA and ACS.

II-VI Aerospace & Defense and its parent company, II-VI, Inc., are industry leaders in the production of infrared optical crystals and other specialty materials. II-VI is one of the foremost manufacturers of infrared materials for military applications. Our sister division in Saxonburg, Pennsylvania, II-VI Infrared, is a leading producer of zinc selenide, zinc sulfide, and Multi-Spectral zinc sulfide materials.

Zinc Selenide (ZnSe)

Zinc Sulfide (ZnS)

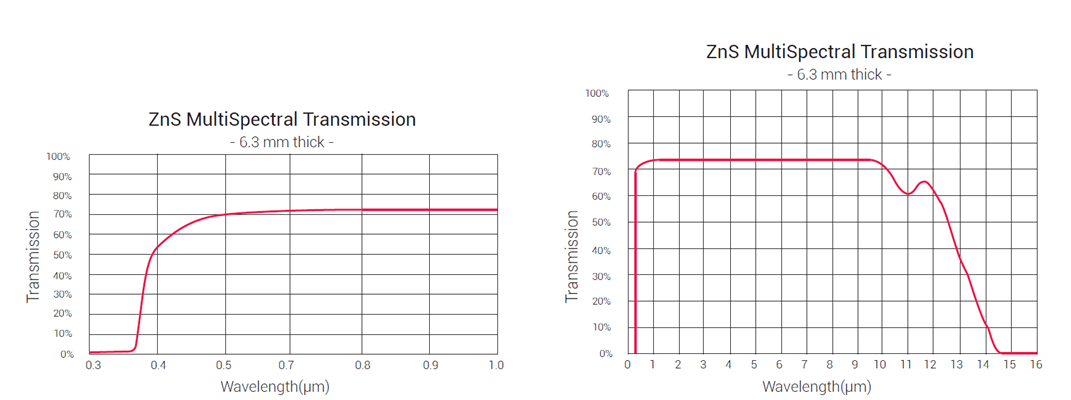

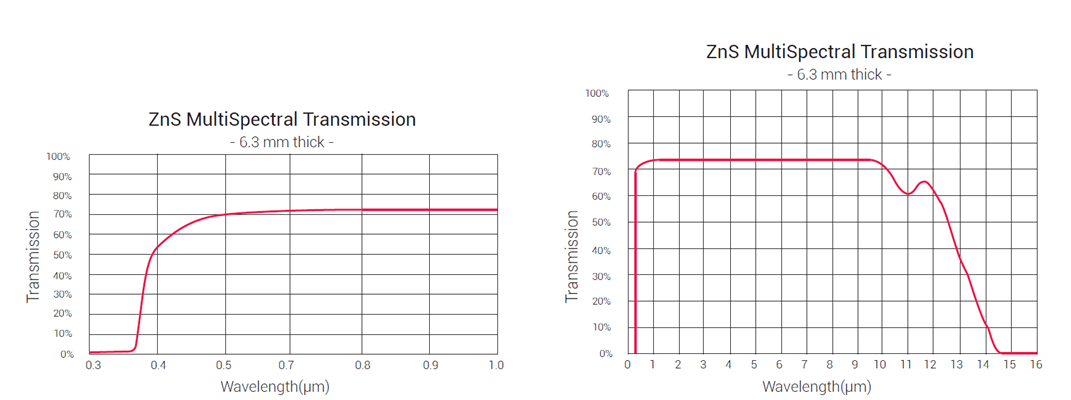

Multi-Spectral Zinc Sulfide (ZnS-MS)

Material Data:

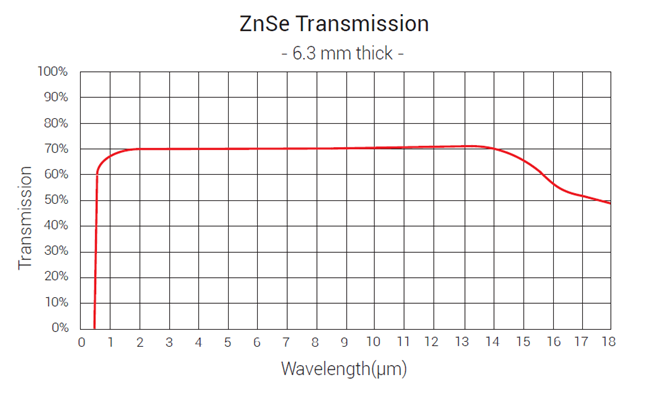

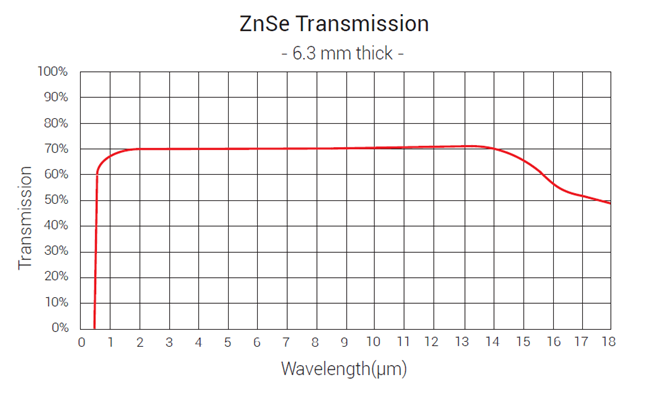

CVD Zinc Selenide (Transmission Curve)

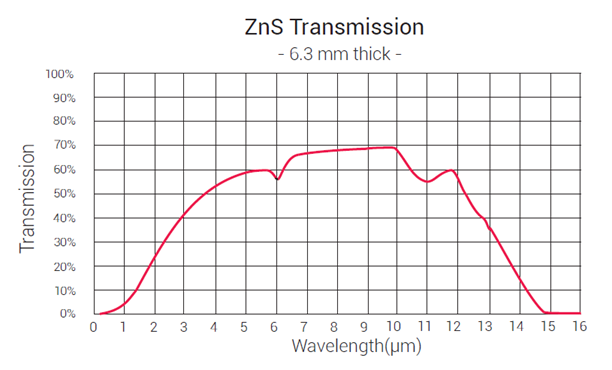

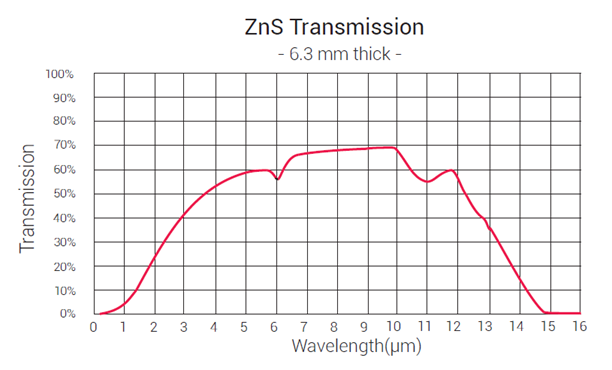

CVD Zinc Sulfide (Transmission Curve)

Multi-Spectral Zinc Sulfide (Transmission Curve)

II-VI Aerospace & Defense world-class material experts and growth operation produce both sapphire boules and sapphire panels that provide extraordinary mechanical strength, high optical transmission, and low Transmitted Wavefront Distortion (TWF). These attributes make sapphire a preferred material choice for many domes, windows, and window assemblies for military and aerospace applications.

Accurate fluorescence lifetime testing, precision Nd concentration measurement, broad-band transmission spectroscopy and active laser testing assures that each crystal will meet or exceed customer specifications.